Abrasives

|

Steel Shot

|

|

Steel Grit

|

| (Note: Other metallic abrasives can also be used) |

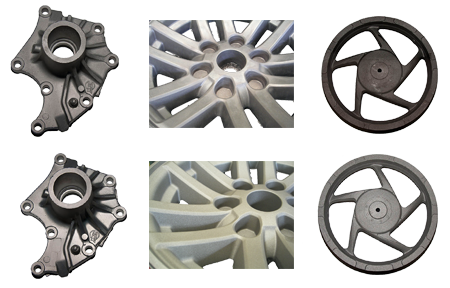

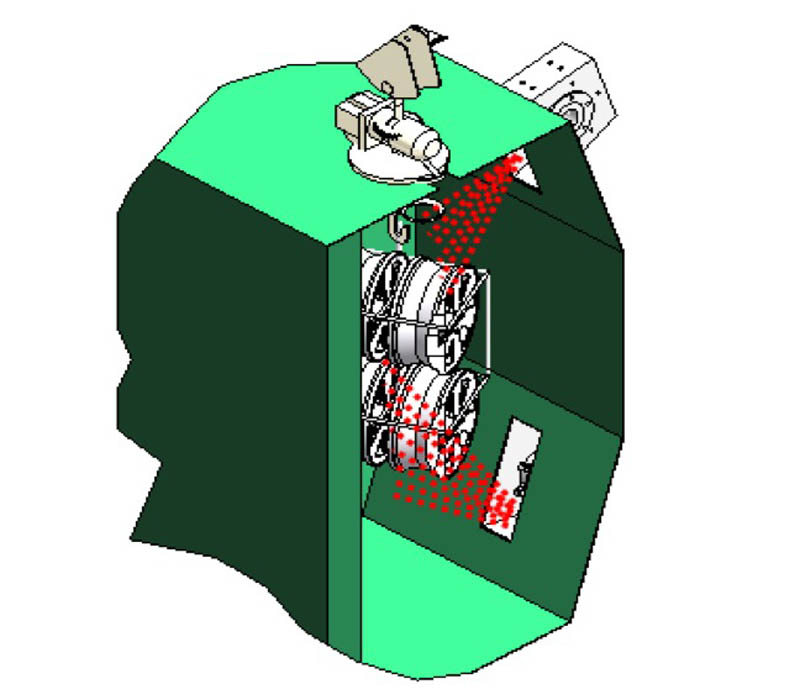

Workpiece Samples

The Tochu Front Hanger Shot Blasting Machine Type TFH (formerly knows as TCFH) is suitable for blasting small to medium sized workpieces. The single hanger, which is located inside the blasting chamber, is loaded with aluminum die-casting workpieces or small iron castings which are mainly used in the automotive industry. This machine is designed in a way that the dust collector is incorporated into the main body of the machine, therefore limiting the space requirements.

- Compact machine design minimizes space requirements

- Convenient loading and unloading of workpieces

- Easy operation and maintenance

- Low investment costs

| MODEL TYPE |

TFH-2A

|

TFH-2FT

|

Max. diameter of workpiece hanger

|

400 mm

|

700 mm

|

Height of workpiece hanger

|

750 mm

|

1400 mm

|

Max. loading weight per hanger

|

50 kg

|

75 kg

|

Average cycle time (e.g. die-casting workpiece)

|

10 min |

8 min |

Number of blast wheels & capacity

|

1 x 3 Hp (2.2 Kw) |

2 x 10 Hp (7.5 Kw)

|

Air consumption

|

8 cfm at 6 bar |

12 cfm at 6 bar |

Total power requirements

|

10 Hp (7.5 Kw)

|

25 Hp (18.5 Kw)

|

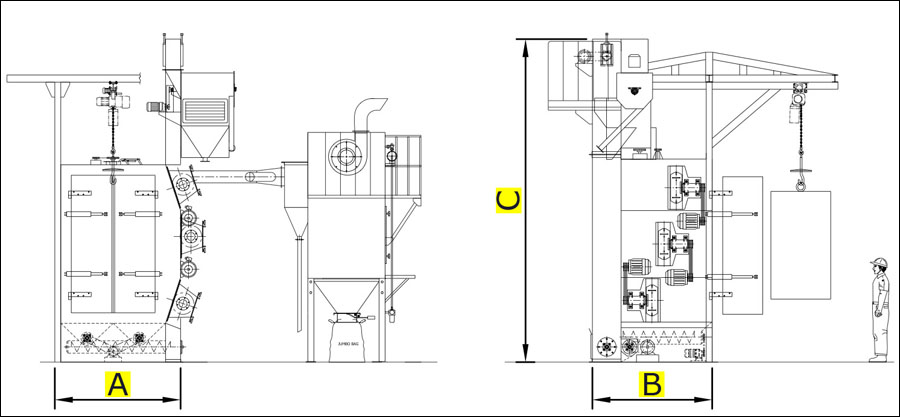

Machine dimensions

|

A 1400 mm

B 2100 mm

C 3600 mm

|

A 1700 mm

B 2500 mm

C 4100 mm

|