Abrasives

|

Steel Shot

|

|

Steel Grit

|

| (Note: Other metallic abrasives can also be used) |

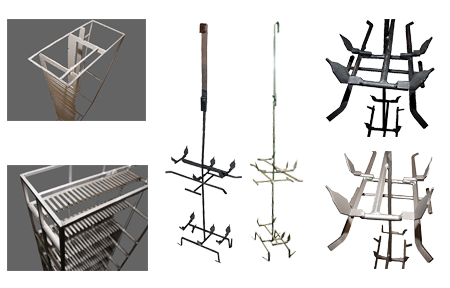

Workpiece Samples

The Tochu Jig Stripper Shot Blasting Machine Type TJS is used to strip the coating from jigs. These workpiece fixtures require regular removal of the coating to ensure repeat and continuous usage.

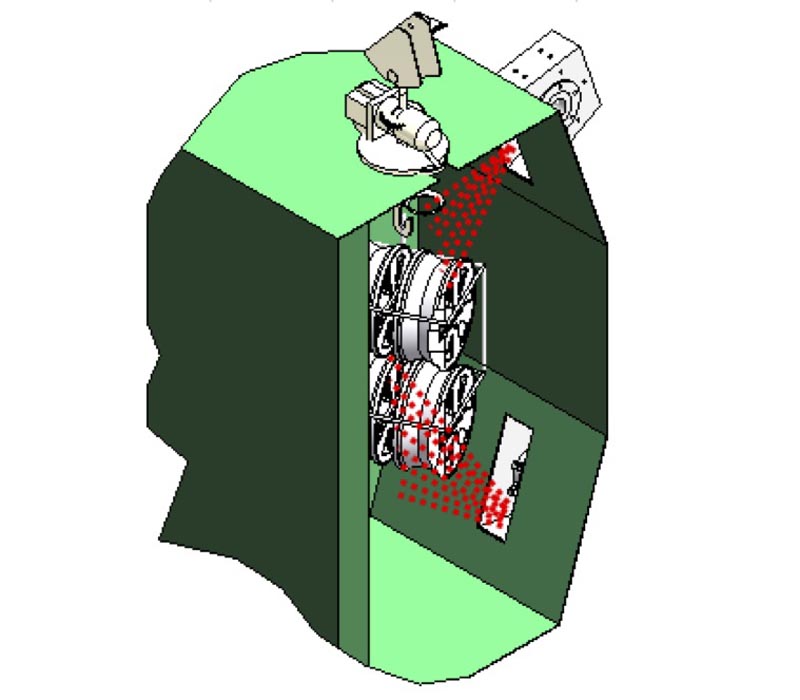

An additional application for this machine is the descaling of other smaller steel structures or parts. Various types of abrasive can be used (copper, zinc or stainless steel shot) and the angled positioning of the blast wheels ensures full exposure of the workpieces to the abrasive stream, resulting in a very efficient blasting result.

- Easy operation and maintenance

- Low initial investment costs

- Low operational costs

- Low maintenance costs

- Compact machine design minimizes space requirement

| MODEL TYPE |

TJS-2RA-300E |

| Max. diameter of workpiece hanger |

500 mm |

Height of workpiece hanger

|

1 000 mm |

| Max. loading weight per hanger |

75 kg |

| Average cycle time (e.g. die-casting workpiece) |

300 sec |

| Number of blast wheels & capacity |

2 x 7.5 Hp (5.5 Kw) |

| Air consumption |

18 cfm at 6 bar |

| Total power requirements |

24.5 Hp (18.15 Kw) |

| Machine dimensions |

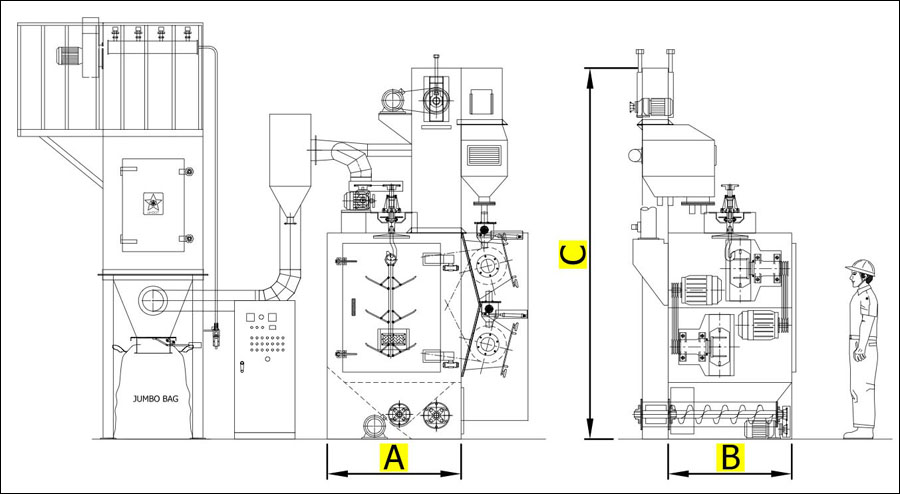

A 1300 mm

B 1200 mm

C 3600 mm |