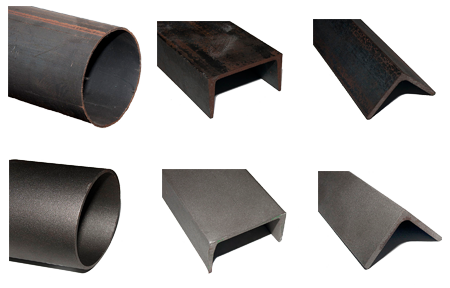

Abrasives

|

Steel Shot

|

|

Steel Grit

|

| (Note: Other metallic abrasives can also be used) |

Workpiece Samples

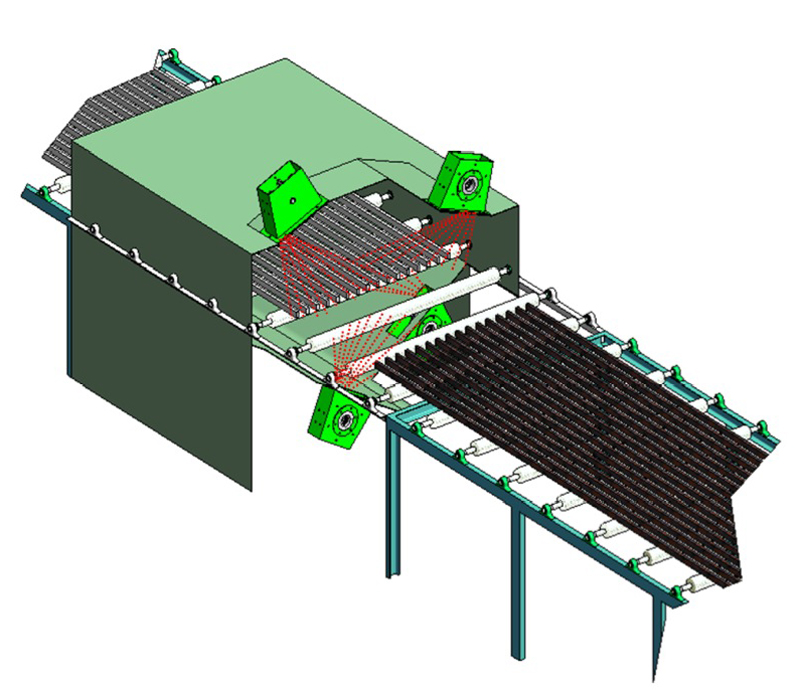

The Tochu Roller Conveyor Shot Blasting Machine Type TRC is a highly efficient surface preparation solution for the cleaning and descaling of raw materials such as plates, beams, angles, pipes and simple prefabricated steel structures. Variable conveyor speeds ensure that the required surface finish up to white metal finish Sa3 can be achieved. This kind of equipment is used mainly by Steel Fabricators, Shipyards and customers in the Oil & Gas Industry.

- Cabinet lined with high wear resistant liners

- Easy replacement of wear parts

- Abrasive and dust free workpieces after blasting

- Variable speed adjustment of conveyor

- Can be installed in-line

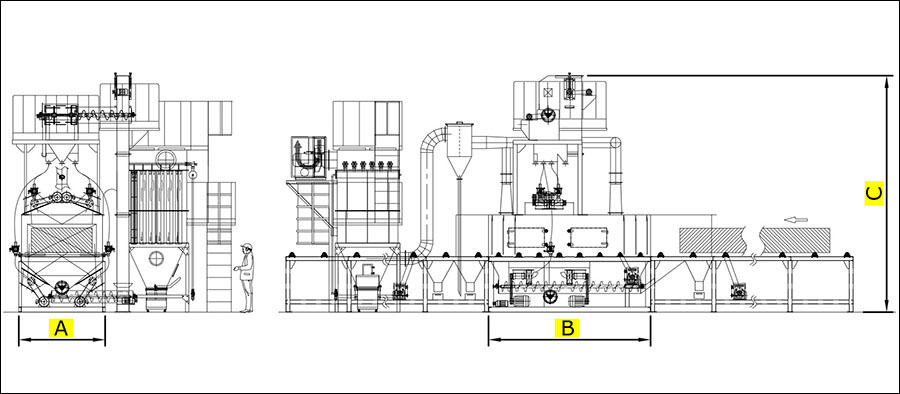

TRC-4RA371

| MODEL TYPE |

TRC-4FT90 |

TRC-4RA371 |

Max. width of workpiece

|

1200 mm |

1500 mm |

Max. height of workpiece

|

350 mm |

600 mm |

Min. length of workpiece

|

3000 mm |

3000 mm |

Number of blast wheels & capacity

|

2 x 7.5 Hp (5.5 Kw)

2 x 10 Hp (7.5 Kw) |

2 x 15 Hp (11 Kw)

2 x 20 Hp (15 Kw) |

Air consumption

|

18 cfm at 6 bar |

18 cfm at 6 bar |

Total power requirements

|

60 Hp (44.75 Kw) |

101 Hp (75.25 Kw) |

Machine dimensions

|

A 1730 mm

B 3500 mm

C 4950 mm |

A 2130 mm

B 4000 mm

C 5850 mm |