Abrasives

|

Steel Shot

|

|

Steel Grit

|

| (Note: Other metallic abrasives can also be used) |

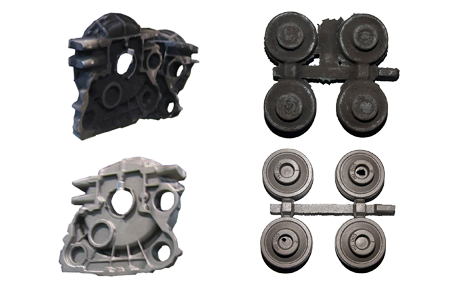

Workpiece Samples

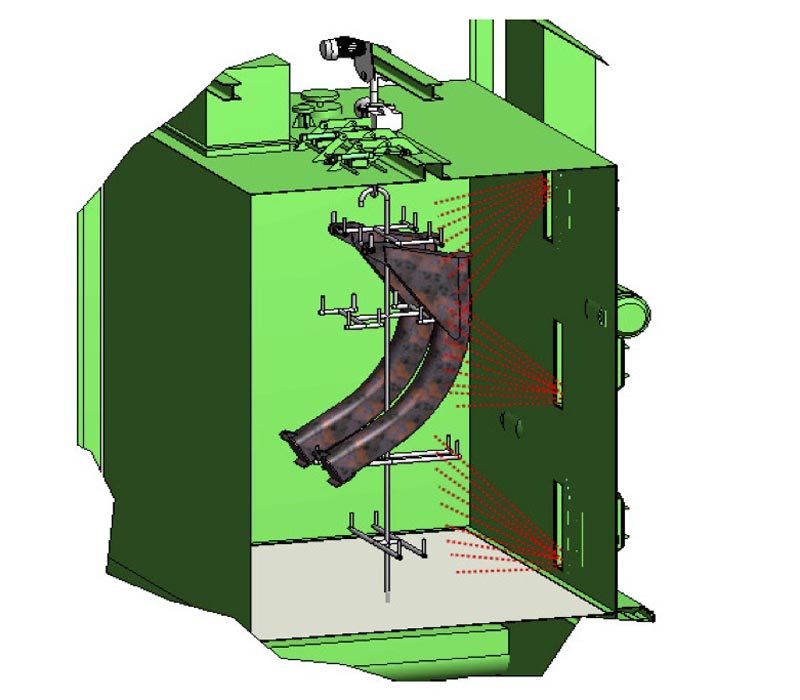

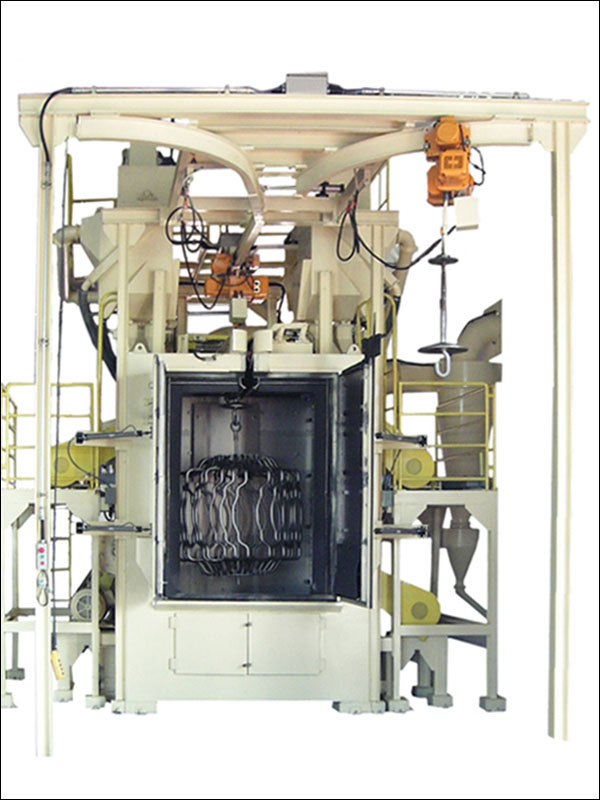

The Tochu Monorail Shot Blasting Machine Type TMR is a very popular choice for customers that require cleaning and/or removal of sand from large, heavy cast iron and steel castings. In addition to these basic cleaning tasks the machine can perform shot-peening of various workpieces, such as springs, gears and industrial spare parts.

- Convenient workpiece handling due to chain hoist lifting hook

- Fully automated transport of parts during the process cycle

- Blasting of complex part shapes is possible due to blast wheel locations

- Compact machine design minimizes space requirements

- Various monorail layouts available

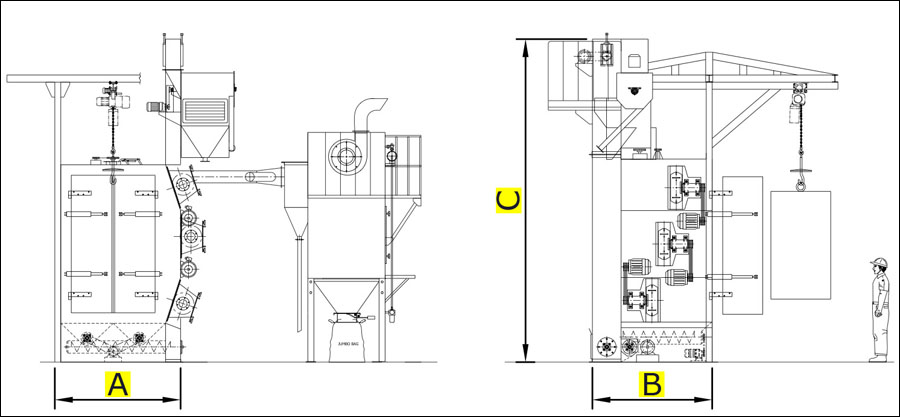

TMR-1T-3FTY

| MODEL TYPE |

TMR-1T-2FTY |

TMR-1T-3FTY |

Max. diameter of workpiece hanger

|

800 mm

|

800 mm

|

Height of workpiece hanger

|

1200 mm

|

1500 mm

|

Max. loading weight per hanger

|

1 ton

|

1 ton

|

Number of blast wheels & capacity

|

1 x 7.5 Hp (5.5 Kw)

1 x 10 Hp (7.5 Kw)

|

2 x 7.5 Hp (5.5 Kw)

1 x 10 Hp (7.5 Kw)

|

Air consumption

|

18 cfm at 6 bar |

18 cfm at 6 bar |

Total power requirements

|

35.5 Hp (26.5 Kw)

|

39.5 Hp (29.5 Kw)

|

Machine dimensions

|

A 2000 mm

B 2000 mm

C 4400 mm

|

A 2200 mm

B 2450 mm

C 5700 mm

|